Customized industrial electric nano infrared band heater with high quality generates high heat by high-resistance wires which is reflected by quartz halogen heating tubes. It has high thermal efficiency, excellent energy-saving effect and quite low heater surface temperature.

Under the support of our customers, we continue to develop new teflon coated immersion heater, wago thermocouple terminal block, ptfe tape and research new technologies and strive to create better products for our customers. The products adopt high-quality raw materials and advanced technology with a complete set of quality management system to make the product quality stable. While developing ourselves, we are also continuously providing various technical support to our counterparts.

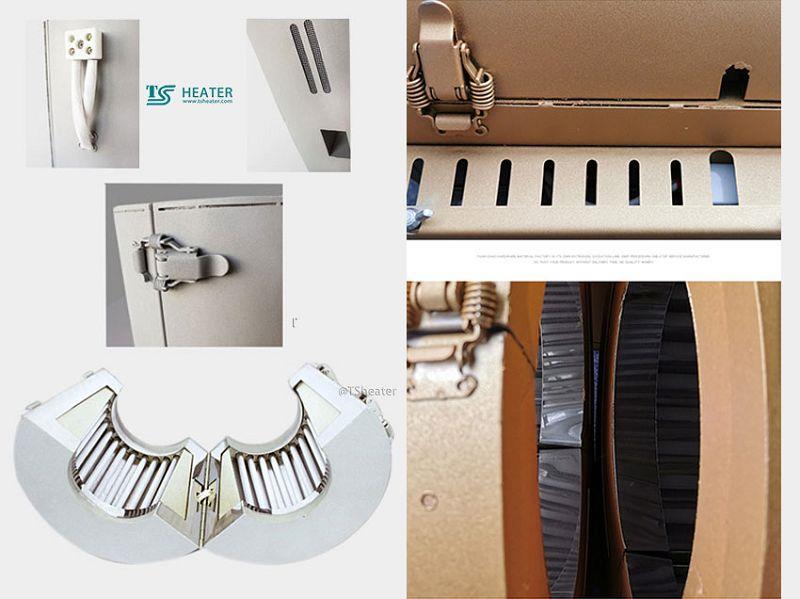

Customized industrial electric nano infrared band heater with high quality generates high heat by high-resistance wires which is reflected by quartz halogen heating tubes. It has high thermal efficiency, excellent energy-saving effect and quite low heater surface temperature. Following induction heating, it is another high energy-saving heating technology which is now widely used in plastic machines.

Advantage:

1. Improve electro thermal conversion rate – over 99.8% (nano carbon silicon material) .

2. Improve heat transmission efficiency (zero medium heat radiation, specific wave length infrared radiation).

3. Reduce heat loss (thick nano insulation layer).

4. Energy-saving rate: 30%-70%.

5. Surface temperature is around 50℃- significantly improves workshop environment.

6. Simple installation – just like installing normal resistance heaters.

7. SUS cover which is stable and long usage life.

Details:

ceramic heater

Power Source:Electric

Dimension(L*W*H):OEM

Weight:Customized

Condition:New

Place of Origin:Guangdong, China

Model Number:TS-NJY-PD

Voltage:230V

Power(W):500W-1700W

Certification:CE,ROHS,ISO9001,TUVNORD

Ceramic band heaters:Nano infrered heaters

Cover:SUS304

Use condition:environment temperature-20-60 degree C,Relative temperature<80%

Leakage current:<0.5MA

Ground resistance:>=5M

Standing the highest temperature:400℃

Energy Consumption:reduced by 30%

Maximum surface loading rate:8 W/Square Centimetre

Usage:heating for extrusion,casting and down-stroke machines

Material:electrical resistance heater

Warranty:2 YEARS

After-sales Service Provided:Engineers available to service machinery overseas

We are committed to offer:

*Reasonable facotry price

*Flexible MOQ

*On-time delivery

*OEM and design service

Supply Ability

2000 Piece/Pieces per Month Nano infrered heaters

Packaging & Delivery

Packaging Details customized by factory in plywood case

Port: SHANGHAI &GUANGZHOU

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto 'High High quality, Competitive Rate, Fast Service' for Far Heating Element IR Ceramic Infrared Heater Plate for Thermoforming. Our directly-affiliated factories can directly serve end customers, save the profits of middlemen, and give the maximum benefits to customers. In the future, with the rapid development of the world economy, the prices of raw materials remain high and resources are short.