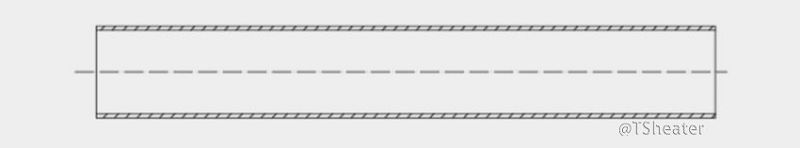

1. Cut the tube according to the length need.

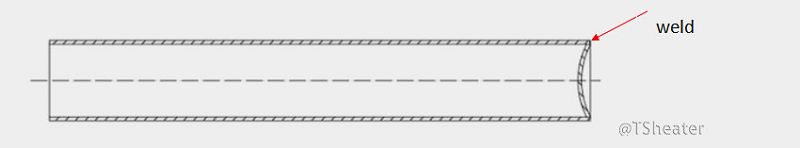

2. Weld the bottom of the tube

3. Buy MGO rods from factory. (the style of MGO rods depend on your requirement and technology)

4. Coil the resistance wire on the MGO rod

Cartridge Heater Machine

Catalog

Cartridge Heater Machine

1. Cut the tube according to the length need.

2. Weld the bottom of the tube

3. Buy MGO rods from factory. (the style of MGO rods depend on your requirement and technology)

4. Coil the resistance wire on the MGO rod

5. Put the nickel wire or iron wire inside the MGO rod hole.

6. Weld the end of resistance wire with iron wire.

7. Put the assembled resistance wire with MGO rods in the middle of the tube

8. Put the tubes on filling machine to fill MGO powder.

9. Seal the filled heaters by sealer (Pic 5)

10. Reduce heater to increase density.

11. Polish the surface of heater (if need)

12. Centerless grinde

13. Trimming the end of the tube (move the plastic sealer out, and dig MGO powder.)

14. Cover with sealer

15. Weld power output wire.

High Density Cartridge heater Mainly steps

Cartridge Heater Machine

1.Cut the tube according to the length need.

Machine: CT-15, CT-30 or ZCT-40 PLC (according to the diameter need to cut and customers requirement)

Item: CT-15 tube cutting machine

Cartridge Heater Machine

cut the tubes according to the length. Change the chuck can cut related diameter tubes.

Rotating Speed: 900rmp 1800rpm;

Max Inner Diameter: Φ15mm;

Air supply:0.6Mpa clean compressed air.

Cartridge Heater Machine

Item: CT-30 tube cutting machine

Cartridge Heater Machine

Max diameter cut: φ30mm

Air supply: 0.6 MPA clean compressed air

Item: ZCT-40 PLC full auto tube cutting machine

Cartridge Heater Machine

Suitable cut diameter: φ6-φ12mm

Air supply: 0.6 MPA clean compressed air

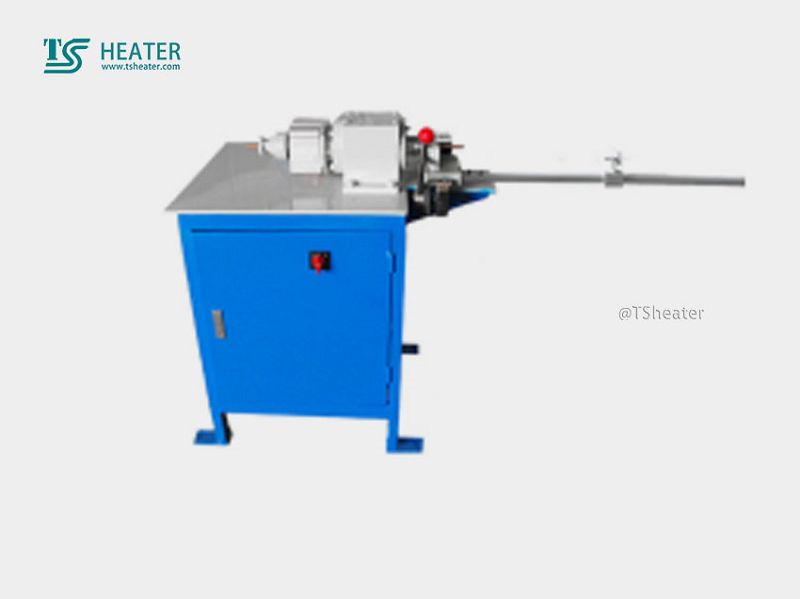

2.Weld the bottom of the tube

Machine: XHJ-200 Auto Rotary Welding Machine

Cartridge Heater Machine

Weld the bottom of the tubes.

Air supply:0.6Mpa clean compressed air.

Speed of mainshaft: 0-100 revolutions/min.

We use a metal pc with hole for weld sample, when you weld the tubes for cartridge heater, should use without hole.

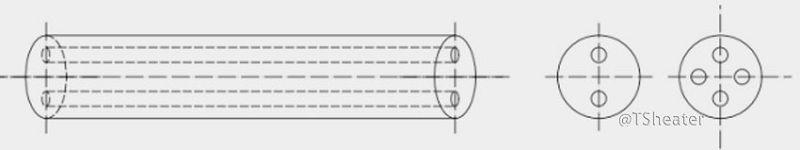

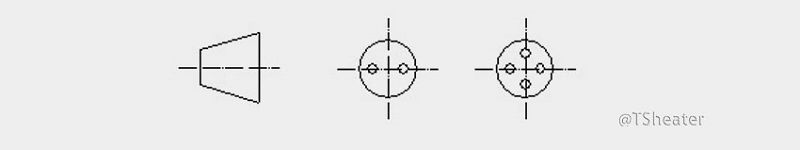

3.Buy MGO rods from factory. (the style of MGO rods depend on your requirement and technology)

4.Coil the resistance wire on the MGO rod.

Machine: DRS23 PLC Resistance Winding Machine

Cartridge Heater Machine

Max. length:Φ500mm

Min. diameter: Φ0.07mm

wind the resistance on magnesium bar.

Rotationl Speed: 0-300 rpm

winding thread pitch : 0-10mm

power: AC220V 50HZ

5. Put the nickel wire or iron wire inside the MGO rod hole.

6. Weld the end of resistance wire with iron wire.

7. Put the assembled resistance wire with MGO rods in the middle of the tube

8. Put the tubes on filling machine to fill MGO powder.

Cartridge heater put MGO rod inside first, and then fill MGO powder.

with magnesium rod fixed position (If diameter <Φ9.5mm, recommend choose this machine)

(put the magnesium rod inside the tube by human,and then put on the machine to fill MGO powder )

1. One time fill 12 pcs tubes

2. Filling length:250-500mm

3. Filling tube diameter: Φ4-Φ20mm

4. Power: AC380/220V 50HZ

5. Air supply:0.6Mpa clean compressed air

9.Seal the filled heaters by sealer

10.Reduce heater to increase density.

There are mainly 3 styles of reducing machine to choose for cartridge heaters, depend on the length, diameter and requirement of factory.

A. ZSG40 OR ZSG60 swaging machine (main machine for cartridge heater)

Machine Type:Pipe Rolling Machine

Name:Stainless Steel Pipe Embossing Machine Rotary Swaging Machine

Type:manual

Voltage:380V

Function:reducing

Material:steel, stainless steel

Power:7.5kw

Time of molding:7-30

Amount of die mold open and close:50mm

Oil pressure motor power:4kw

Measurement size of machine:2500*800*1500

Model/Name | ZSG40 | ZSG60 |

Max. reducing capacity mm | Φ40×2.0 | Φ60×2.5 |

Max. reducing length mm | 260 | 320 |

Molding time m | 10-60 | 10-60 |

Motor power KW | 5.5 | 7.5 |

Cooling oil pump W | 40 | 90 |

Rotate speed of main shaft r/min | 175 | 286 |

Overall dimension mm | 1020*620*1200 | 1300*880*1300 |

Weight T | 1.4 | 1.6 |

B. SG reducing machine such as SG8B,SG12B (depend on the diameter and length need to reduce)

Cartridge Heater Machine

roll the heaters after filled with MGO powder to reduce the diameter, then increase denisty of MGO powder.

1.Large power,single power can be 1.1kw,1.5kw,2.2kw;

2.Large torque,large power,more suitable for high density tubes, large tubes and long tubes;

3.Noise is a little large than A style machine. (similar as OAKLEY machine, speed down by gear);

4.The best reference range to shrink (mm): Φ4-Φ16mm;(within the reference range, the life of the equipment will be longer).

5.Suitable tubes' material: copper, aluminum, iron, stainless steel etc.;

6.Suitable tube's shape: round tubes.

7.Shrinking speed: uniform speed,non-uniform speed (according to the demand of customer).

8.Chang different rollers or roll assemble can reduce different size elements.

Need to change roller or roll assemble for different diameter heater reducing.

Min reduce length: 200mm.

Suitable for one or several diameters cartridge heaters reduce, and in bulk production. (reduce efficiency higher than DG30)

DSG12A reducing machine for short heater

Cartridge Heater Machine

After fill with MGO powder, reduce the heaters to increase density.

1.Large power,single power can be 1.1kw,1.5kw,2.2kw;

2.Large torque,large power,more suitable for high density tubes, large tubes and long tubes;

3.Noise is a little large than A style machine;

4.The best reference range to shrink (mm): Φ4-Φ25mm (within the reference range, the life of the equipment will be longer).

5.Suitable tubes' material: copper, aluminum, iron, stainless steel etc.;

6.Suitable tube's shape: round tubes, flat tubes, oblate tubes, composite tubes.

6.Shrinking speed: uniform speed,non-uniform speed (according to the demand of customer).

11.Polish the surface of heater (if need)

Cartridge Heater Machine

Machine: PG-30 polishing machine

Use to polish the surface of the tubes

MAIN TECHNICAL PARAMETER:

1.Suitable material: copper,steel,stainless steel

2.Suitable size:Φ6-Φ15mm

Centerless grinde

Cartridge Heater Machine

If your heater’s diameter tolerance is strict , so you need this machine to be ground finished for tube. ( tolerance ‘s range : ±0.02mm)

If your heater’s diameter tolerance is strict , so you need this machine to be ground finished for tube. ( tolerance ‘s range : ±0.02mm)

13.Trimming the end of the tube (move the plastic sealer out, and dig MGO powder.)

Cartridge Heater Machine

CG20 roll turning machine

Trimming the end of the heaters.

Air supply:0.6Mpa clean compressed air.

14.Cover with sealer

15.Weld power output wire.

Delivery & Enquiries:

Most items are available for delivery in 3 to 7 working days. However, Ts heater do offer additional emergency services for customers who are in a breakdown situation. This includes a 48hr services on Mica products, Cartridge Heaters and Ceramic Knuckle Heaters. For all enquires please contact a member of our sales team who will be happy to assist.